Diesel Engine Tips and Information

Overview

Diesels have no spark plugs. They obtain the heat necessary

for combustion by gathering the heat content of the outside air

and putting it

into one small area. The result is an increase of temperature. If 50F degree

air is compressed at a ratio of 20 to 1, it

will yield air at 1,000F degrees (20x50=1000).

Diesel fuel will instantly combust when sprayed into such a hot and oxygen

rich

environment. The rate at which the compression takes place has little

influence on temperature. In other words, it doesn’t matter

how fast

you crank a diesel. What matters is the outside air temperature and the

volatility of the fuel. The most common problems

with a diesel center around

fuel quality and fuel delivery problems. One needs to pay particular attention

to the bleeding of high

pressure and low pressure fuel lines and also the

stoppage of filters. If you get your fuel right, a diesel will almost always

run.

A.

Bleeding Fuel Lines

Because a diesel engine is highly efficient, it injects only

a very small amount of fuel into the cylinder with each stroke. It

can take a

huge amount of engine cranking to work out an air bubble. That is why

bleeding air out of fuel lines is so very important.

First, check the low pressure fuel line

to see if fuel is getting to the injection pump. The best way to do that is to

remove the

fuel hose on the end closest to the pump. Keep a rag handy and reattach

the fuel hose while the fuel is still running out. It does cause

a mess,

but is the most effective way to eliminate air bubbles.

Next, bleed the high pressure fuel line.

That is done by loosening the steel pipe ferrule on the high pressure fuel line

closest to the injector. Set the throttle to maximum, hold down the compression

release lever and crank the engine over until a small drip of fuel comes past

the connection. Retighten the fuel line, reset the throttle to one half

and you are ready to start the engine.

B.

Breaking an engine in

Modern synthetic oils are amazing products. However, you

don’t want to use them in a new engine. Synthetics lubricate so very well

that a new engine will never seat the rings properly. It is

best to start a new engine with frequent oil changes of a non-synthetic oil for

the first 100 hours. After the engine has been broken in, then switch to a good

synthetic. You will find that these small diesel engines will deliver an

amazing amount of service if properly maintained.

C.

Cold Weather Starting

A diesel engine considers anything below 40F degrees to be

cold weather and can be hard to start. That's because there isn't

enough heat content in the outside air to get the temperature of compression

high enough to detonate the diesel fuel. Another problem is that oil companies

change the fuel formula from summer to wintertime blends.

If you get stuck with summer fuel in a

winter situation, then a diesel can be just about impossible to start. Take a

tip from the "old time" truckers. They would mix about 5% gasoline to

their fuel to assist in cold weather starting.

Glow plugs on these small diesels are

available, but end up being a wasted effort. The glow plugs are mounted in the

manifold, not in the cylinder. These diesel engines are not typically used in

wintertime applications, so the manufacturers just don’t provide for

proper glow plugs inside the combustion chamber.

If you really need to run one of these

engines in the winter, then I would go the 5% gasoline fuel mix and find some

way to heat the engine crankcase and especially the incoming air. I have

successfully used a hair dryer to blast warm air down the intake manifold to

raise the temperature of compression.

D.

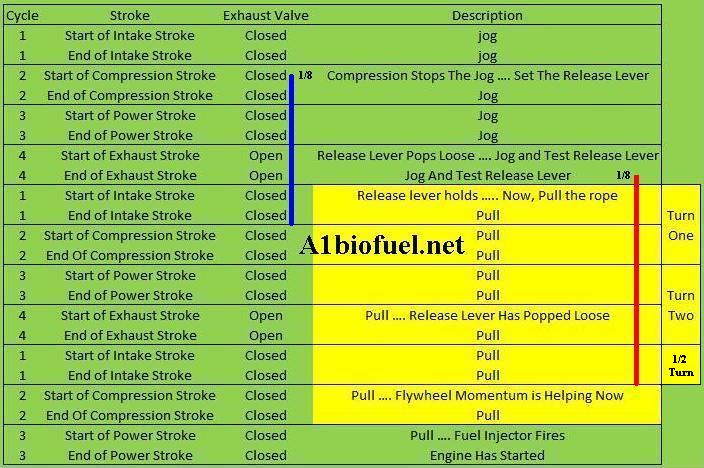

Recoil Starting

The high compression of diesels can make

them hard to recoil start. Almost

everybody

knows to jog an engine up to the compression stroke, set the

compression

relief and pull start the engine. This old method yields about

2 turns of pull before the next compression stroke. There is a

trick

that will get

you a full 1/2 turn more of momentum on the flywheel.

To do that, set the compression relief

lever. Slowly jog the engine over until it releases. You are now on the exhaust

stroke. Keep slowly jogging the engine and pressing the relief lever until it

will hold down again. You are now at the end of the exhaust stroke. Give the

rope a long, hard pull. The secret is in the long pull. The intention is

to get as much momentum as possible into the flywheel to start the engine.

Another compression stroke actually does come around, but it is skipped because

an exhaust stroke did not precede it. You jogged your way past it. The

compression stroke after the skipped one is the stroke the engine will fire on.

Don't believe me? Try it .... or check out the table listed

below: Keep in mind that the compression relief lever keeps the exhaust valve

slightly open until the cam actuates the exhaust valve and loosens the

compression release lever.

In reality, the situation is a little more extreme than that. In the old method (blue line on the chart) compression stops the crank part way into the compression cycle. That "part way" will give you a little less than 2 turns of remaining pull .... probably 1/8 of a turn (a guess).

With the new method (red line on the chart),

the compression lever will start to hold a little before the exhaust

stroke is complete. Let's guess that also at 1/8 of a turn. But that 1/8

turn is added

to

your potential pull. That gives you a total of 2-3/4 turns

of pull. That additional 3/4 of a turn can make a lot of

difference between a start

and a no-start situation. Examine the chart below.

E. Diesel Smoke.

Diesel

smoke is unburned fuel. The

only way to reduce how much a diesel smokes is to reduce the

unburned

fuel. Either decrease the fuel input or increase the amount of

oxygen to

the engine. Turbo chargers do a good job of oxygen increase. In

non-turbocharged engines, the only choice is to decrease fuel input for

the

present load. That may mean downshifting to reduce load. Or a

person can get an engine that is oversized and simply not work it

as hard. Increasing throttle position beyond the torque an engine can

produce

does not increase power or speed. It just increases smoke.

F.

Compression Relief Compression relief is a very useful thing. Useful in reducing wear and tear on

the starter and also when bleeding fuel lines. It's an absolutely necessity when rope

starting. A compression relief can also stop a diesel "run away" condition.

Unfortunately, due to the popularity of electric starters

and the lack of general diesel knowledge by the public, manufacturers are

beginning to discontinue the compression relief lever. Lower cost is probably also a

reason. I wish they wouldn't do that, but it is probably a reality

we must live with in the future.

G.

What is Diesel Run Away?

Diesel run away only happens with extremely worn out engines and usually only

if they have become very hot. What happens is that on the intake stroke the

piston draws some air from the crankcase that is rich with oil mist, past

the rings into the combustion chamber which acts as a fuel. Because there is no

control over the air intake, the engine will continue to run on its'

own even when the fuel has been shut off. It will keep running until it

has exhausted the crankcase oil and possibly seize the engine.

It's a bad situation and doesn't happen

very often. The only way to stop the engine is either hold down the compression

relief lever, stall the engine or find some way to totally cut off the intake

air.

H.

Electrical Considerations

These engines are designed for off-road stationary power

use and to just recharge the battery from starting. People have used them for all kinds of things .... lawn mowers,

rototillers, stump grinders, electric power, sawmills, garden tractors

and even crazy stuff like sailboats, motorcycles and airplanes. It is

possible to increase the windings in the stator and about double the electrical

output. If you need more than 8 or 10 amps, then check out the forum on

dieselbike.net. A member there called "ThunderCougarFalconBird" has

posted a good series on how he rewound a stator with good success.

I.

Battery Size

Question: How big a battery should I use?

Answer: As big as you physically have

room for.

A battery will wear out in direct proportion as to how hard it

has to work. The typical garden tractor size battery seems to work very well

with these engines. People have used motorcycle batteries, but I would suggest

you get the biggest one you can fit into your battery box.

J. Low Battery Dangers Danger One:

An inertia type starter won't have the proper "quick spin" to fully

engage the pinion gear and grinding of teeth will result. Danger Two: Probably the most serious situation is that a solonoid type starter can keep running and explode the armature!

What happens is the battery voltage has dropped off,

so the starter pulls more amps to compensate. The electrical contacts

can "weld" together and keep the starter running. The only way to stop

the starter is to remove a battery cable. Not an easy thing to do in a

panic situation. Eventually the bushing on the starter drive will

lock and spin up the armature with enough centrifugal force to

make the windings fly apart. A big battery that is discharged seems to

cause this more often than a small battery that is discharged.

K.

Starter Fluid

Oh what a very big No No!

About the only problem we have had with

these engines is with starter fluid. Typically someone runs out of fuel and has

trouble restarting the engine. That's because these is now air in the fuel

lines. So, they attempt to "pop it over" as you would do a gasoline

engine and run it long enough to get fuel worked through the engine.

That is not going to work for two reasons.

Reason One: Diesels are very

efficient and only inject a very small amount of fuel on each stroke. It can

take a very long time to crank out an air bubble. Opening the throttle all the

way and holding down the compression relief will help, but still it's a whole

lot of cranking and you will probably run down the battery several times before

the bubble is worked out.

Reason Two: Because of the high

temperature of compression the starter spray will ignite before top

dead center and cause engine to kick backwards. If the engine kicks back fast, it

will usually break the starter drive gear or the starter nose cone. If it kicks

back slow enough, it can get the armature spinning in reverse and cause

enough centrifugal force to cause the armature to explode.

If you run out of fuel you need to bleed

the fuel lines. A word to

the wise is never run a diesel dry and never, never introduce any type

of fuel into the intake manifold.

L.

Starter Types

The most common complaint we have is about starters.

Normally it is a result of fuel issues, bad batteries or starter

spray that has caused over work or damage to the starter. If

a person is aware of the various types of starters and their various

strengths and weaknesses, then possibly damage to the starters can be

reduced.

1. Inertia Drive Starters

Inertia drive starters are the most

common type found on small engines. They are small and inexpensive to

manufacture.

They work just fine, however they do suffer from a few problems. If they lose

lubrication on the worm drive they will have problems with kicking in. Also,

they need a fully charged battery to insure a quick snap of the armature

to kick in the drive gear without grinding teeth.

2. Solenoid Starters

The public is more familiar with

solenoid

starters as they are the same type found on automobiles.

They

will kick in fine with a low battery but will just crank slowly. That's

a good thing because the average person will understand that their

battery is weak.

2. Solenoid Starters

The public is more familiar with

solenoid

starters as they are the same type found on automobiles.

They

will kick in fine with a low battery but will just crank slowly. That's

a good thing because the average person will understand that their

battery is weak.

3. Gear Reduction Starters

Gear reduction starters are the

best.

They are more expensive to manufacture, but are smaller and

generate a large amount of starting torque. They are more

efficient, so

they are more tolerant of an undersized or weak battery. Normally

they are considered to be optional equipment. The one cylinder engines

do fine on a direct drive starter. Most of the v-twin engines do have direct drive starters, but we are encouraging the

manufacturers to make gear reduction starters standard for all the v-twin engines.

3. Gear Reduction Starters

Gear reduction starters are the

best.

They are more expensive to manufacture, but are smaller and

generate a large amount of starting torque. They are more

efficient, so

they are more tolerant of an undersized or weak battery. Normally

they are considered to be optional equipment. The one cylinder engines

do fine on a direct drive starter. Most of the v-twin engines do have direct drive starters, but we are encouraging the

manufacturers to make gear reduction starters standard for all the v-twin engines.

M.

Vibration Issues

1. The one cylinder diesels seem to run pretty

smooth. They have

an internal counter balance shaft that runs at the same speed as the

crank

shaft but in the opposite direction. It will cancel

most of the vibration from piston movement. Experts have argued

that you cannot

cancel a linear vibration with a rotational vibration. In the

strictest

theoretical sense that is true. However you can reduce the overall net

vibrational

effect with the proper use of a counterbalance shaft. The Winsun 13hp

engine

runs particularly smooth for being a light weight diesel engine.

2. The v-twins are another matter. There

is no practical way to mount a counter balance shaft that will cancel the

complex vibrations of a 90 degree v-twin engine. All v-twin engines

vibrate to some degree. Usually they will have one or two "sweet spots". The problem is not

all that bad .... Harley Davidson motorcycles have always suffered from vibrational

problems and there are thousands of them running down the highways every day. Ken

Mosi built a Punsun v-twin scooter that has a directly bolted down engine.

He rides the scooter every day to work and has no problem.

3. The only vibration issue we have experienced is

sometimes on a v-twin, the thin steel high pressure fuel line will

crack from vibration. I understand from diesel truck mechanics that

this is a common problem. It is due to the individual harmonic

vibration frequency of a particular fuel line. Repair is by replacement

of the fuel line and possibly adding some support or a loop to change

the natural resonant frequency of that line. Fortunately, it is a fairly simple

and inexpensive repair. The lines are standard metric sizes that almost

any hydraulic supply house can fabricate one if you give them the old line

as a sample.

N.

Flywheel Stub Shafts and Custom Power Shafts

From time to time we get requests for engines with stub

shafts on the flywheel or custom size power shafts. People are trying to

replace the engine in their unusual make or model garden tractor or lawn

mower. In the past, we have made attempts to have the factories in China

manufacture these items. The willingness and friendliness of the Chinese

manufacturers has been good. Unfortunately, the results of these custom jobs

has not turned out to be as good as one would hope. Both the V-twins and 1 cylinder engines come

with 1 inch diameter power shafts only.

Although we have sold many successful lawn

mower and garden

tractor replacements, we want to leave the custom work in the hands of

the

consumer. We are a low cost diesel engine supplier and have no

facilities to do custom machine work. Please do not ask us to

arrange or do

custom machine work. All the custom stuff is up to you.

M.

Vibration Issues

1. The one cylinder diesels seem to run pretty

smooth. They have

an internal counter balance shaft that runs at the same speed as the

crank

shaft but in the opposite direction. It will cancel

most of the vibration from piston movement. Experts have argued

that you cannot

cancel a linear vibration with a rotational vibration. In the

strictest

theoretical sense that is true. However you can reduce the overall net

vibrational

effect with the proper use of a counterbalance shaft. The Winsun 13hp

engine

runs particularly smooth for being a light weight diesel engine.

2. The v-twins are another matter. There

is no practical way to mount a counter balance shaft that will cancel the

complex vibrations of a 90 degree v-twin engine. All v-twin engines

vibrate to some degree. Usually they will have one or two "sweet spots". The problem is not

all that bad .... Harley Davidson motorcycles have always suffered from vibrational

problems and there are thousands of them running down the highways every day. Ken

Mosi built a Punsun v-twin scooter that has a directly bolted down engine.

He rides the scooter every day to work and has no problem.

3. The only vibration issue we have experienced is

sometimes on a v-twin, the thin steel high pressure fuel line will

crack from vibration. I understand from diesel truck mechanics that

this is a common problem. It is due to the individual harmonic

vibration frequency of a particular fuel line. Repair is by replacement

of the fuel line and possibly adding some support or a loop to change

the natural resonant frequency of that line. Fortunately, it is a fairly simple

and inexpensive repair. The lines are standard metric sizes that almost

any hydraulic supply house can fabricate one if you give them the old line

as a sample.

N.

Flywheel Stub Shafts and Custom Power Shafts

From time to time we get requests for engines with stub

shafts on the flywheel or custom size power shafts. People are trying to

replace the engine in their unusual make or model garden tractor or lawn

mower. In the past, we have made attempts to have the factories in China

manufacture these items. The willingness and friendliness of the Chinese

manufacturers has been good. Unfortunately, the results of these custom jobs

has not turned out to be as good as one would hope. Both the V-twins and 1 cylinder engines come

with 1 inch diameter power shafts only.

Although we have sold many successful lawn

mower and garden

tractor replacements, we want to leave the custom work in the hands of

the

consumer. We are a low cost diesel engine supplier and have no

facilities to do custom machine work. Please do not ask us to

arrange or do

custom machine work. All the custom stuff is up to you.

(Bottom

of Page)